Hybrid Rocket Propulsion Pressure Monitoring

.

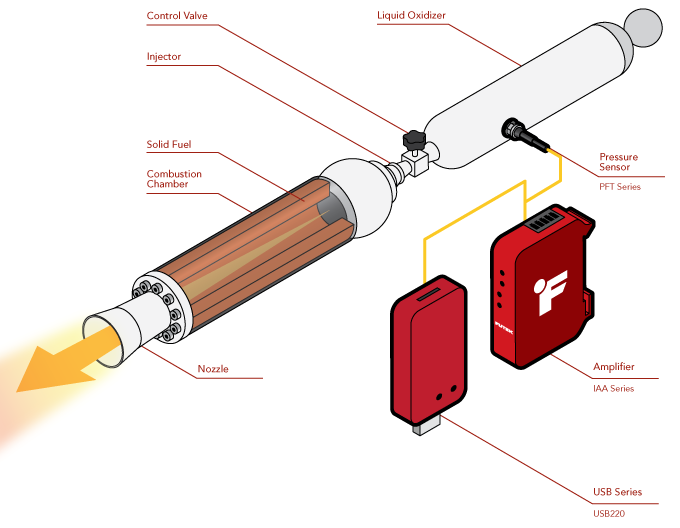

Pressure monitoring is a critical feature of hybrid rocket engine design, testing, and operation. With gaseous or liquid components, rapid pressure spikes in the system can cause catastrophic failure. With monitoring systems in place, complex actions can be taken before failure or activation of pressure relief systems, thus preserving the system and the mission. In addition, pressure monitoring can provide feedback on system performance, allowing for system optimization. Typical pressure measurement sensors on the market are limited to a natural frequency of 1 kHz, while the PFT510 series features natural frequencies between 6 kHz and 100 kHz.

How it works :

- A PFT series flush diaphragm pressure transducer is screwed in to measure the pressure of the inner walls of the oxidizer tank.

- During operation, the tank pressure is measured by the pressure sensor.

- The output is then transferred and recorded via the USB530 to a PC using the SENSIT software or to a PLC via a high frequency signal conditioner type IAA300.

.

.