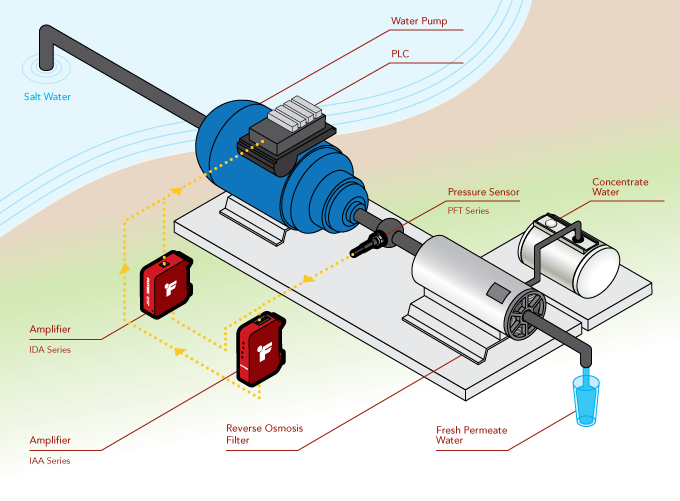

Desalination System Monitoring

.

Access to clean water is a necessity for every person in the world. In many drought-stricken regions, fresh water is limited while salt water from the ocean is very abundant. The conversion of salt water to fresh water is most often done by high pressure reverse osmosis. These systems require a constant pressure provided by a pump system to maintain membrane quality and maximize system efficiency. By incorporating a pressure sensor into a loop control system, the pump can maintain a constant operating pressure for maximum efficiency.

How it works :

- A miniature PFT510 series pressure transducer is installed between the outlet of the water pump and the inlet of the reverse osmosis filter.

- The output signal of the pressure sensor is amplified with the amplifier of the IAA or IDA100 series and sent to a PLC.

- The PLC regulates the power of the motor in response to pressure changes to maintain a constant output pressure.

- By maintaining a constant pressure, filter life is increased and system efficiency is maximized.

- In addition, with the IDA100, the amplifier output can be monitored and adjusted using its USB connection and SENSIT ™ software.

.

.