Laparoscopic grasper with force perception

.

How does this force sensing device improve haptic feedback ?

In laparoscopic surgery, grasping instruments are the only source of force feedback for the surgeon. Due to the lack of haptic perception and communication of the tool, surgeons can damage tissue by using incorrect control of the laparoscopic grasping force, and the unpredictable properties of the tissue and the graspers can cause slippage or even tearing. This article on haptic feedback robotic surgery presents an in-depth review of the topic.

To overcome this challenge, a miniature force sensing solution can be installed in-line with the control wires, creating a haptic feedback control system for the endoscope that helps to :

- Influence the surgeon's ability to perform a safe laparoscopic grasp while pulling and manipulating tissue of varying stiffness.

- Improve the surgeon's ability to detect tissue consistency, arterial pulse detection, and force control during surgical procedures.

.

Force feedback sensor design challenges :

Engineers and surgeons face significant issues that must be considered prior to designing a force sensing laparoscopic forceps. Designing and manufacturing a haptic feedback sensor for robotic surgical instruments involves two distinct but complementary challenges :

Overcoming the technical hurdles of designing a sensor for intra-abdominal force measurement such as :

- Size restrictions - miniaturization;

- Biocompatibility;

- Autoclavability;

- Hermeticity;

- Reusability.

Maintain the minimum specifications required for a high quality force measurement solution such as :

- Non-linearity;

- Hysteresis;

- Repeatability;

- Crosstalk;

- Bandwidth;

- Noise-free resolution.

.

Why are FUTEK's nanosensors up to these challenges ?

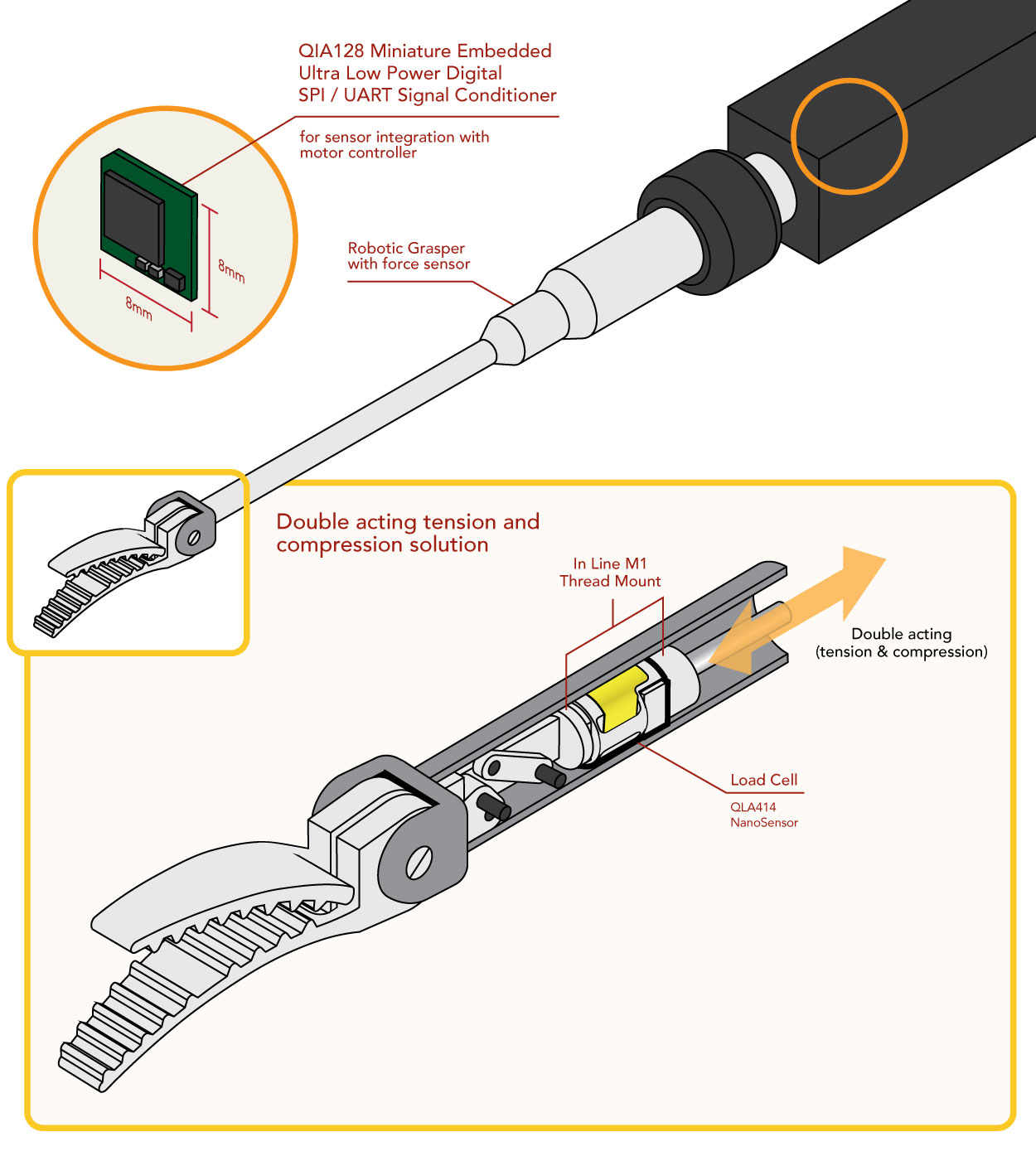

The QLA414 nanosensor was designed with all these design constraints in mind. It was also developed with a design-for-manufacturing approach.

The QLA414 series is the smallest tension and compression force measurement solution of its kind (micro-miniature in-line load cell). This 4mm x 5mm sensor opens up a world of possibilities for robotic surgery with its tiny size, ability to measure both tension and compression, and unique mounting flexibility.

QLA414 Features :

- Double-sided M1 threaded mounting arrangements;

- Instrumentation compensated by a full bridge side load of 1000 Ohm (off axis or extraneous loads) ;

- Laser welded structure;

- Non-active interconnection;

- Environmental Protection;

- Non-linearity of ±0.5% of rated output (RO) in 5lb and 10lb capacities - high accuracy force measurement applications;

- Safe overload up to 200% ;

- Tension and compression force transducer;

- Ultra-low deflection (0.005 mm);

- High natural frequency response.

.

In addition, force transducers as small as 3mm x 4mm with force measurement capabilities up to 50lb, are also available for OEM applications, including IP67 and autoclavable transducers for the medical industry. As the ideal miniature force transducer for surgical robotics and laparoscopic forceps with force perception, this sensor is perfectly suited for haptic force feedback and ultra-miniature catheter force measurement.

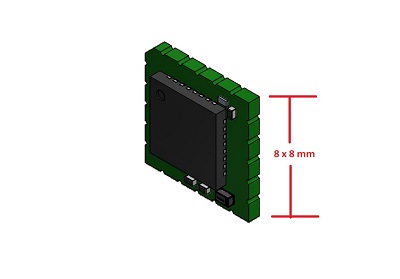

QIA128 Onboard Digital Signal Conditioner

The QIA128 Embedded Digital Signal Conditioner is an ultra-low power miniature device with SPI output. Its small 8 mm x 8 mm board offers a selectable sampling rate from 4 SPS to 1300 SPS to achieve a noise-free resolution of 11.4 to 14.2 as required.

.

Transducer Calibration Requirements

Due to the criticality of surgical instruments, force feedback transducers must provide high accuracy and be subject to a strict in-situ calibration regime. Depending on the criticality of the application, the haptic force transducer must be recalibrated before each surgical procedure.

In addition, engineers must understand the correlation between the in-line force applied by the actuator and guide wires to the nanosensor inside the instrument trocar, and the actual physical gripping force of the jaws applied to the tissue.

To address the challenge of in situ calibration, our microengineering team also developed a bite reference sensor to enable calibration and inspection of the surgical clamp jaws and the actual force applied.

How does it work ?

- Two QLA414 nanosensors are installed in-line with the axial guide that controls the movement of the forceps jaw. It measures the forces in tension (open jaw) and compression (closed jaw).

- Since the gripper is in contact with the internal tissue during the surgical procedure, the nanosensor measures the force applied by the gripper.

- The force measurement signal is then read by the miniature QIA128 ultra-low power digital signal conditioner with SPI output. This provides force feedback to the surgeon's control system (the gimbal).

.

Products used :

- QLA414 series - Nano force sensor in Traction Compression.

- QLA128 Series - Miniaturized ultra-low power integrable sampling system.

.