Precision Wire Tensioner

.

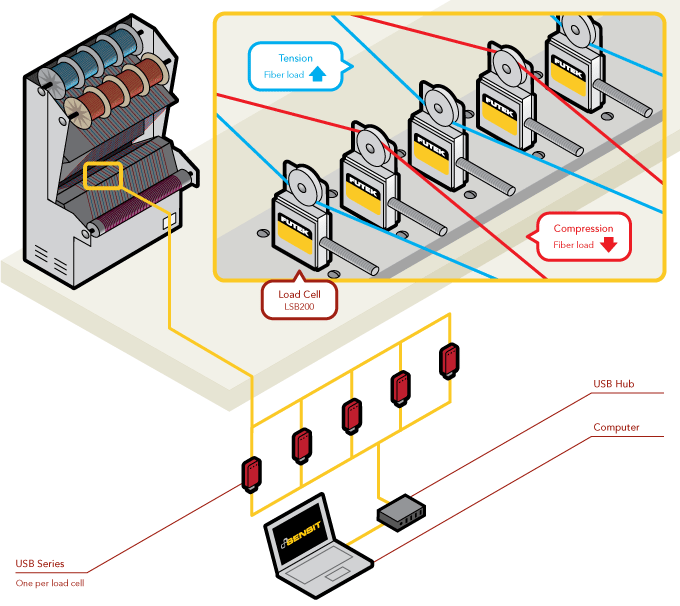

Tension Control in Wire and Cable Manufacturing

The manufacture of wire and cable products requires the maintenance of constant tension to achieve repeatable quality results, minimize downtime and improve operator efficiency. FUTEK cable tension sensors (aka wire tension sensors) can be combined with a closed loop tension controller to provide an automatic loop tension control solution.

FUTEK miniature load cells and cable tension sensors (aka cable tension load cells) can be adapted to a wide range of applications where cable, wire, fiber or cord tension measurement is required.

.

The benefits of wire and cable tension monitoring include :

- Minimizing stretching or breaking during manufacturing

- Optimization of manufacturing speeds

- Fewer entanglement incidents, resulting in less downtime.

- Ability to leverage existing machine and operator capabilities to manufacture a wider range of products.

- Consistent product quality

.

How it works :

- A miniature LCM Series Tension and Compression Force transducer is installed in-line between the wire tensioner and a linear actuator to measure wire tension.

- Adjustment of the linear actuator plunger causes changes in tension on the wire generating a signal at the output of the force sensor.

- The signal from the LCM sensor is then sent to an IAA series signal conditioning amplifier or to an IDA100, a high resolution digital and high speed analog amplifier.

- The amplified signal is then sent to a PLC/controller that drives the linear actuator, closing the control loop and allowing the system to change the stresses on the wire.

- With the IDA100, the amplifier output can be monitored and adjusted simultaneously on a Windows PC with SENSIT software while providing a high speed amplified analog output.

.