Shackle pin load cell

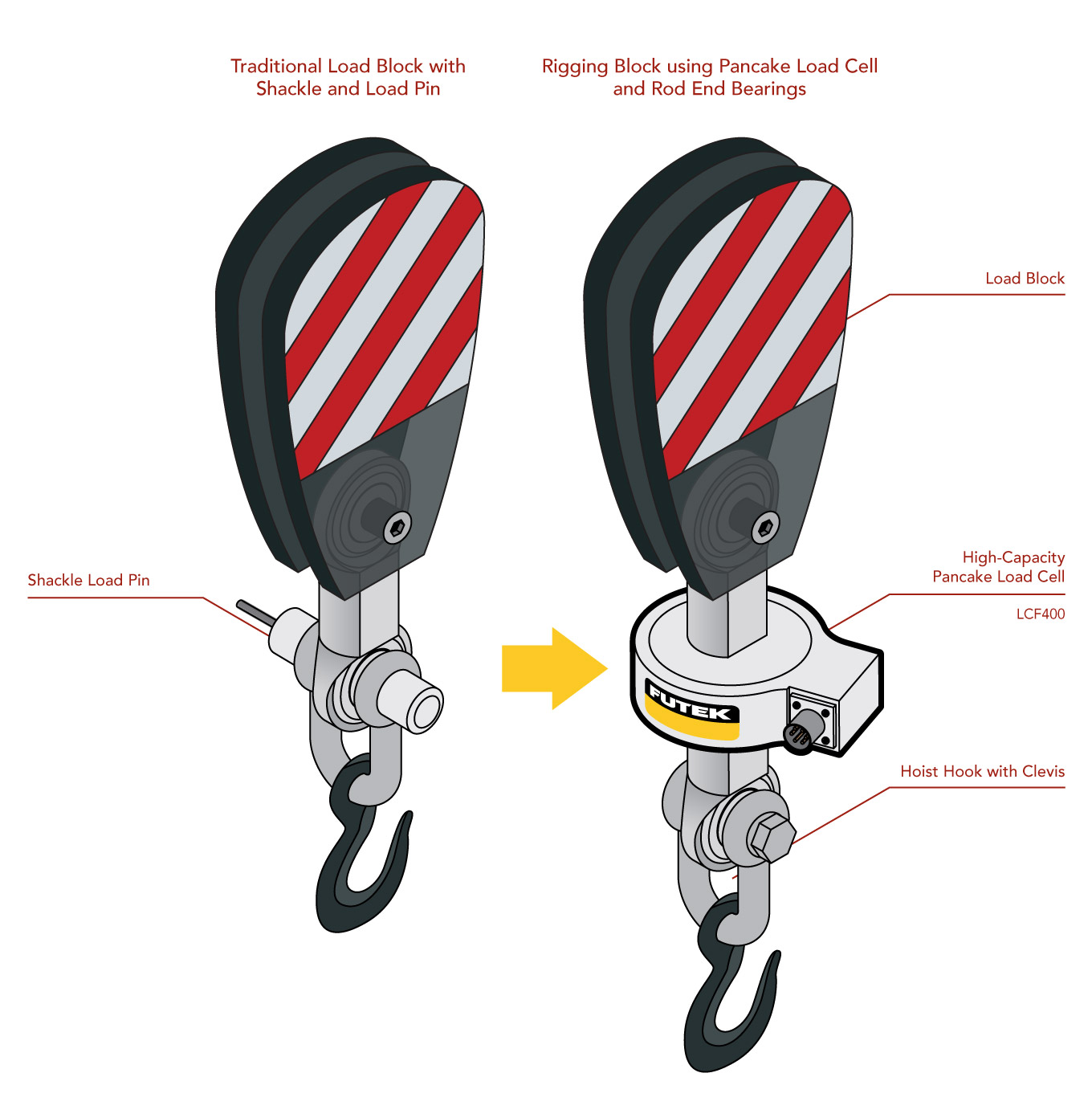

When it comes to measuring loads in weighing, rigging or lifting applications, the most common solutions are either using a shackle with an integrated instrumented load pin, or a custom-made load pin sensor that can fit into the existing shackle, replacing existing shear pins, clevis pins, shear pins or any other type of pin joint. This labor-intensive configuration is resource-intensive, as designing and manufacturing a custom pin load cell is a time-consuming process, especially since the designer must ensure that the load applied to the load pin is centered or evenly distributed in the clevis pin.

FUTEK offers a simpler, yet equally effective solution. Instead of replacing or customizing components, a commercially available "wafer" type load cell can be integrated into the existing load block configuration with minimal interaction with the lift and load block components. A high capacity pancake load cell with axially mounted rod end bearings is connected to the load block and lifting hook using existing shackles and load pins, leaving the existing lifting elements largely untouched.

FUTEK's LCF series of load cells are suitable for capacities up to 100,000 lbs and can withstand up to 150% overload with IP protection up to IP65 (higher seals are available upon request). LCF Series load cells are built to withstand the demands of harsh environments and weather conditions and allow for accurate load monitoring and recording at any attachment point.

FUTEK LCF load cells have fatigue resistance, a feature that is particularly important for fixed and long-term applications. The load cell's ability to withstand successive load cycles for long periods of time without risk of failure or damage to the load cell body (bending) or strain gauge element, saves time and resources while providing peace of mind to the operator.

.

Typical Applications :

- Weighing cranes under hooks

- Show and theater assembly

- Aircraft manufacturing and repair

- Lifting and lowering of loads

- Testing and certification of structural loads

- Shipping and receiving weighing

- Crane and hoist calibration and proof load testing

- Manufacturing and heavy construction

.

Benefits of LCF Series Load Cells :

- Simple installation and operation

- Fatigue resistant load cell

- High accuracy with ±0.10% non-linearity.

- Eccentric loading - capable of withstanding high external loads

- Stainless steel or anodized aluminum flexure

- Ideal for use in rugged or harsh environments

- Environmentally sealed to IP65 (higher sealing available upon request)

- Available up to 100,000 lbs (higher ratings available upon request)

.

How it works :

- FUTEK's LCF "wafer" type load cells are installed between the load block and the lifting hook to measure the crane's lifting load.

- As the load is lifted by the crane or other lifting system, the strain gauge load cell captures the weight of the lifted load in real time. At any time, as the load increases, the operator can reverse the lift in case of overload. A load indicator or digital display is installed in the operator's cab for online monitoring.

- The IPM650 intelligent digital display is combined with sensors for real-time recording, locking and alarming.

- These systems are also available with wireless/Bluetooth solutions for improved versatility and logistics.

.

.

Products used :

LCF series high capacity pancake load cell combined with IPM650 intelligent digital display ;

.